Here we are posting some answer to the most common questions we received about the full metal hot end .

Full Metal Hot End Specs.

The fullmetal hot end is designed to solve the problem that always occur during printing with thermal isolator made of PTFE and PEEK.

Usually both plastics are subject to deformation, note that the difference between the PEEK and the PTFE is only the rigidity, PTFE is more soft but keep the same temperature of the PEEk, almost 250 degrees.

Sometimes with some type of ABS you will need to increase the temperature up to 245 degrees, a rather high temperature for such kind of thermal insulator, especially if they are very close to the heater block. High temperature makes the plastic parts softer and deformable.

It is very important that the channel where the filament slides is very smooth to avoid extra force needed by the extruder, The plastics deformation very often occurs in the joint between the steel or brass barrel and the thermal isolator,

This generates some teeth or slope in the join that makes it difficult for the filament to slide free.

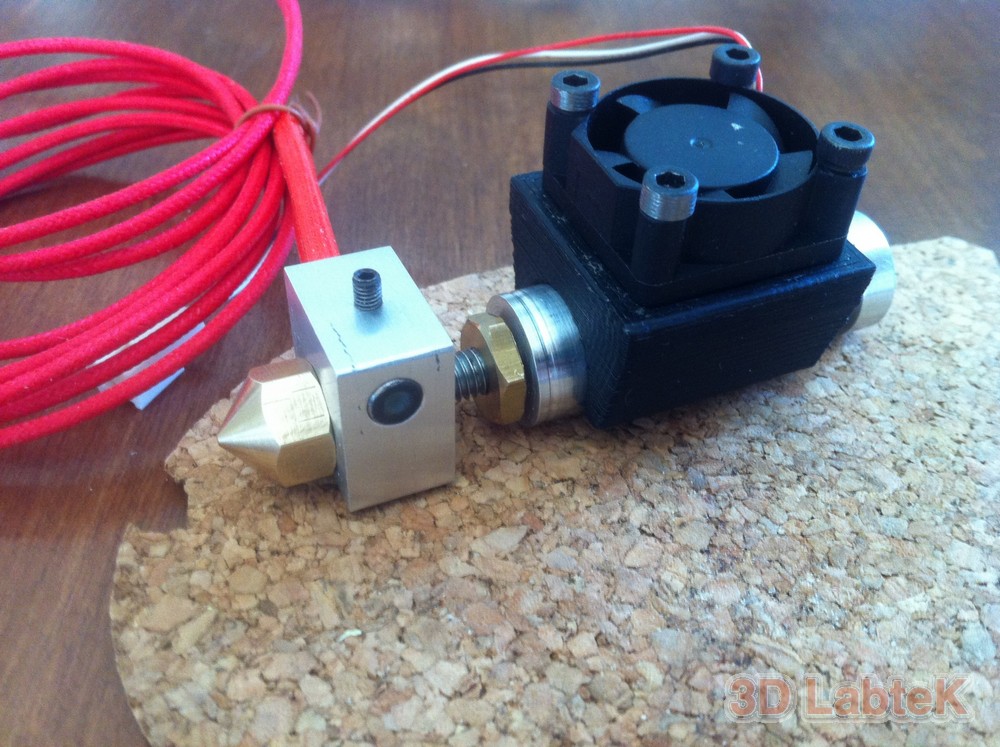

With the Aluminum body the problem is solved , it keeps up to 500 degrees and it is not deforming even when you tighten the barrel inside the body.

We added a fan to the aluminum body, but it is only to prevent the heat to reach the extruder, that is made of Plastic. there is no other purpose.

Bellow there are some answers to the most common questions we receive:

The fullmetal hot end is designed to solve the problem that always occur during printing with thermal isolator made of PTFE and PEEK.

Usually both plastics are subject to deformation, note that the difference between the PEEK and the PTFE is only the rigidity, PTFE is more soft but keep the same temperature of the PEEk, almost 250 degrees.

Sometimes with some type of ABS you will need to increase the temperature up to 245 degrees, a rather high temperature for such kind of thermal insulator, especially if they are very close to the heater block. High temperature makes the plastic parts softer and deformable.

It is very important that the channel where the filament slides is very smooth to avoid extra force needed by the extruder, The plastics deformation very often occurs in the joint between the steel or brass barrel and the thermal isolator,

This generates some teeth or slope in the join that makes it difficult for the filament to slide free.

With the Aluminum body the problem is solved , it keeps up to 500 degrees and it is not deforming even when you tighten the barrel inside the body.

We added a fan to the aluminum body, but it is only to prevent the heat to reach the extruder, that is made of Plastic. there is no other purpose.

Bellow there are some answers to the most common questions we receive:

Bellow there are some answers to the most common questions we receive:

- Should the fan run all the time?

Yes we recommend that the fan run all the time, although in some electronics board you have got fan management and in this case you can control the fan through software. - What is the working temperature?

With ABS the range of temperature varies from 220 to 245 degrees, depending on the type and the Color of the filament.

For PLA from 165 to 180 degrees. - What Kind of fixing for the extruder?

The Hot end can be customized as you wish, Jhead or groovemount or other. For all the types that we already know it is enough to specify the type for the other you should provide measures based on your existing PEEK or PTFE thermal insulator. - What Temperature does the body reach?

Generally the top of the aluminum body is cold enough to be touched by fingers. In some cases it can reach 50 degrees (Celsius).

getting hot very quickly and the fan mount is made by ABS. As you see also the dimension of the body has been reduced from the 30 mm of the experimental to the 16mm of the final version, so now it is standard, like the PTFE or PEEk insulator.

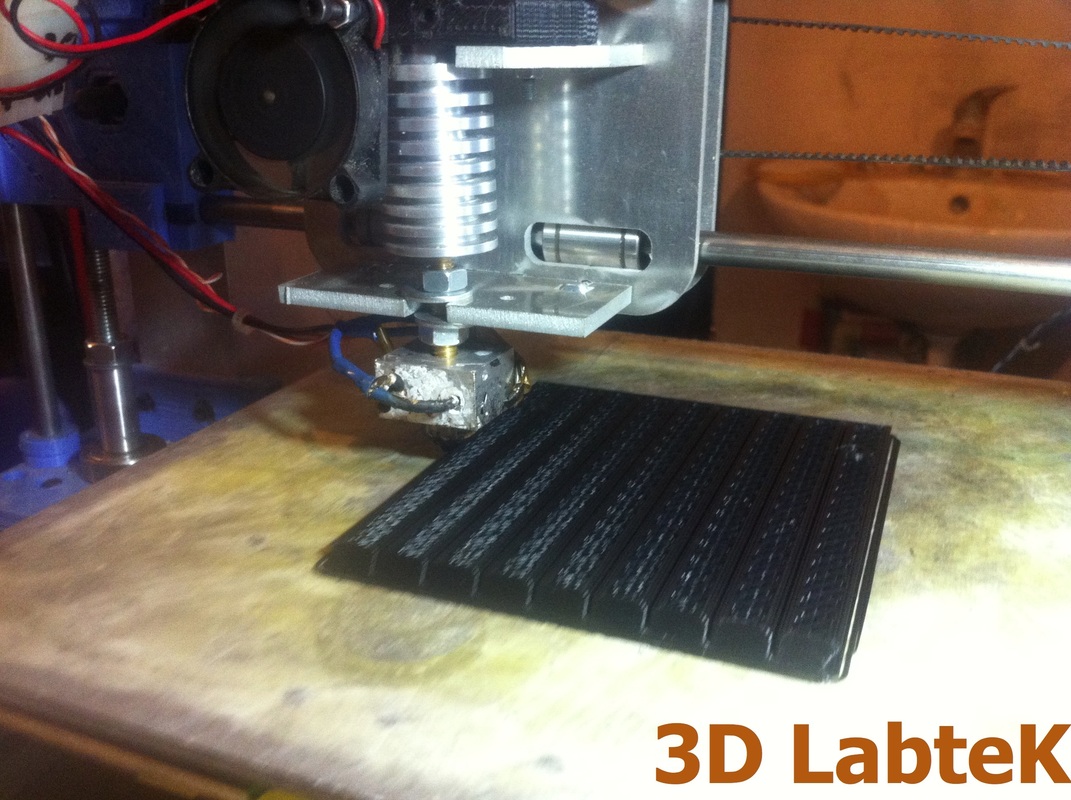

The Version we have tested was an Hot end for 3mm filament, PLA or ABS.

The Full Metal is Available for 3 mm filament and for 1,75mm.

Customer that are interested in 1,75 mm version are kindly requested to contact us.

The Version we have tested was an Hot end for 3mm filament, PLA or ABS.

The Full Metal is Available for 3 mm filament and for 1,75mm.

Customer that are interested in 1,75 mm version are kindly requested to contact us.

RSS Feed

RSS Feed