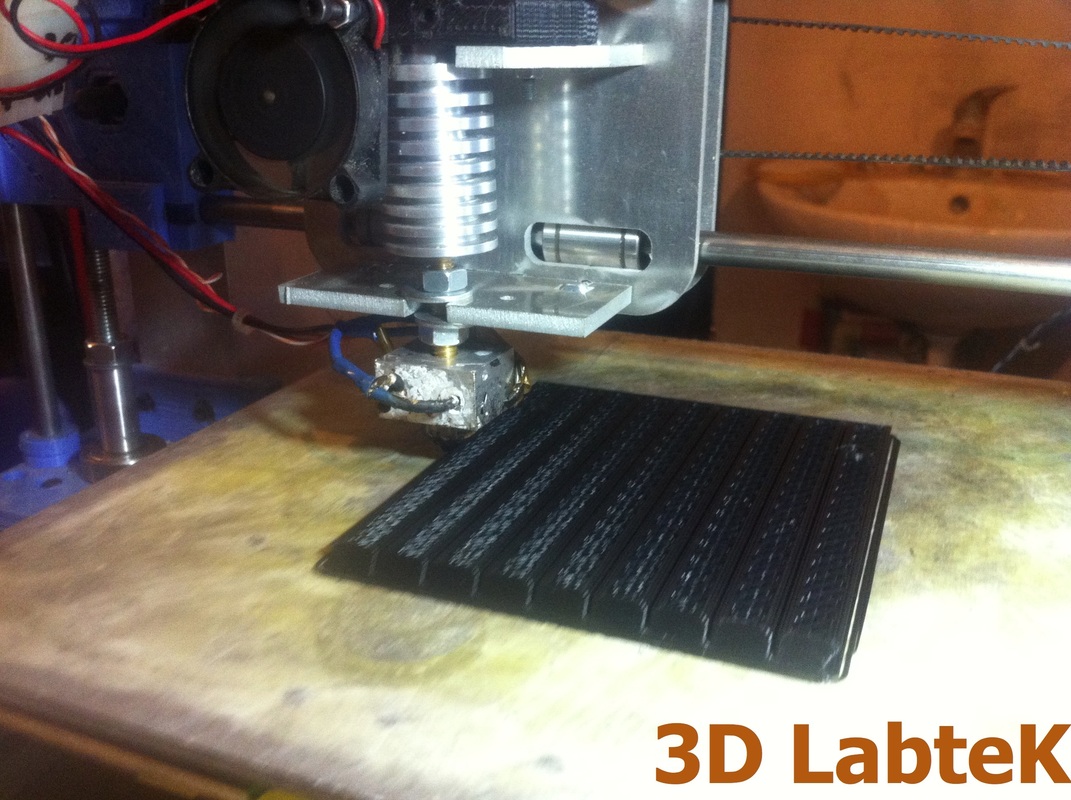

At last we are testing a full metal hot end, that include an Alluminium X-carriage and an universal mounting plate for the extruder.

| the mounting plate allow the installation of the WADE geared Extruder (motor front side), and the Greg's Geared V3 and V2. Further model will be tested soon. In the picture we are printing with 0,5mm nozzle Black ABS at 50mm/s and a temperature of 255 deg. The top part of the body of the extruder has 38 degrees and the fixing plate has almost 100 degrees. |

In the future, the two resistors will be replaced by a powerful heater with almost 40 watts at 12 Volts.

Anyway, with this first test we realize that the combination of the full metal hot-end and the ALU X-carriage give a significant quality improvement.

Anyway, with this first test we realize that the combination of the full metal hot-end and the ALU X-carriage give a significant quality improvement.

| In the picture on the side and on the bottom of this post you can see the layers placement with a layer thickness of 0,3 mm and a width over layer factor of 0,66. The Hot end installed was with the tip Makegear type, but we are studying also a single barrel body, so that the heater block will be easier to dismount and maintained. |

Keep in touch to discover more

RSS Feed

RSS Feed