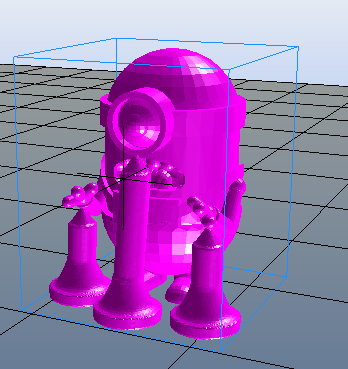

| For the test we used the model of a minion downloaded from thingiverse (pic1) https://www.thingiverse.com/thing:82478 And we scaled down until it reached the measure of one Euro Cent. To create the support for the hands we used meshmixer, the result is shown in the pic2 We printed the model using natural ABS filament at 210 degrees |

| To get a good result at least three attempts were needed, as with regular printing settings the parts detached from the build plate due to the low adhesion area of the foot and the supports base. The second attempt failed because of the Z lift option enabled only when crossing perimeter. The result can be reached drastically decreasing the printing speed, for our test we set to 30 mm/sec, a Z lift double of the layer thickness that occur to each movement, the gap infill set to 0 (disabled) a first layer extrusion width set to 180% and a perimeter extrusion width of 185%. Part cooling on with fan 100% just from the second layer |

Of course your extruder steps per mm must be very accurate, in few words an already calibrated 3D printer

The aim of the test was to look for the best parameter to print very small objects.

Consideration

Performing multiple print of a very small object we realized that the speed is the most important factor, for small object printing. As fast as we go as hot the part will be, with deformation due to the heat generated by the hot end placing layer one over the other very quickly.

Reducing the speed and with the part cooler on, the part has enough time to cool down avoiding deformation and keeping the shape.

the Z lift double of the layer thickness it required as the overhang usually create slope up while cooling due to the tension generated by the plastic segment. the elevation of the Z avoid the accidental touch of the tip with the object during non printing moves that in case of little object can cause detaching from the build plate.

feel free to ask about any other parameter if you may be interested.

The aim of the test was to look for the best parameter to print very small objects.

Consideration

Performing multiple print of a very small object we realized that the speed is the most important factor, for small object printing. As fast as we go as hot the part will be, with deformation due to the heat generated by the hot end placing layer one over the other very quickly.

Reducing the speed and with the part cooler on, the part has enough time to cool down avoiding deformation and keeping the shape.

the Z lift double of the layer thickness it required as the overhang usually create slope up while cooling due to the tension generated by the plastic segment. the elevation of the Z avoid the accidental touch of the tip with the object during non printing moves that in case of little object can cause detaching from the build plate.

feel free to ask about any other parameter if you may be interested.

RSS Feed

RSS Feed