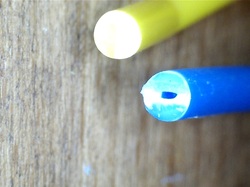

Here is a picture of two pieced of filament for 3 mm ABS.

Of course the Yellow one is a good piece and unfortunately the blue one ..is not!!

Is a matter of fact, that when you buy filament from different supplier you have to change some parameter in your slicer software.

But sometimes even with the best setting you get in trouble with your prints and you waste a lot of material and time looking for a solution.

We want to share with all of you our experience about a filament that we bought on the polish market some week ago. Anyway, that filament was not so cheap, so we did not think the supplier was an improvised filament producer.

AS follow we describe what we found and the problems we had.

Of course the Yellow one is a good piece and unfortunately the blue one ..is not!!

Is a matter of fact, that when you buy filament from different supplier you have to change some parameter in your slicer software.

But sometimes even with the best setting you get in trouble with your prints and you waste a lot of material and time looking for a solution.

We want to share with all of you our experience about a filament that we bought on the polish market some week ago. Anyway, that filament was not so cheap, so we did not think the supplier was an improvised filament producer.

AS follow we describe what we found and the problems we had.

Filament With DefectPrinting these parts we get in trouble with the surface quality and with our extruder Stepping out without flowing the filament. At begin we thought springs were loose or temperature was not properly settled for this type of filament. So we correct these parameter and we get the same result. So we investigate more. the hole in the center of the filament create a lot of problem to the extruder as it compress the filament the force applied vary continuously according with the dimension of the hole. Furthermore is visible on the surface a rough finishing of the surface, with inclusion wisible by eyes. | Good FilamentHere instead a rather good result obtained in the same printer with the same parameter but obviously with good filament. Surface quality of good filament Finally on the left what give us a lot of problems in terms of quality and time wasted looking for the solution. The Filament has got a lot of inclusion that clog your nozzle continuously avoiding a regular flow and a good quality printing. Talking with an expert he told me that the hole in the center is due to wet plastics and low force used in the extrusion to produce the filament, The Inclusion also are due to the original material used for the production of the filament. probably it is not 100% original new plastic, |

As a conclusion we spend 50 hours looking for a solution for a problem that get solved just changing the filament with good one.

As a lesson now we have a certified supplier and we buy plastics only from them. New Supplier are welcome but we will reject their product as soon as we find defect on the surface.

Hope this is going to help other 3D printers User.

As a lesson now we have a certified supplier and we buy plastics only from them. New Supplier are welcome but we will reject their product as soon as we find defect on the surface.

Hope this is going to help other 3D printers User.

RSS Feed

RSS Feed