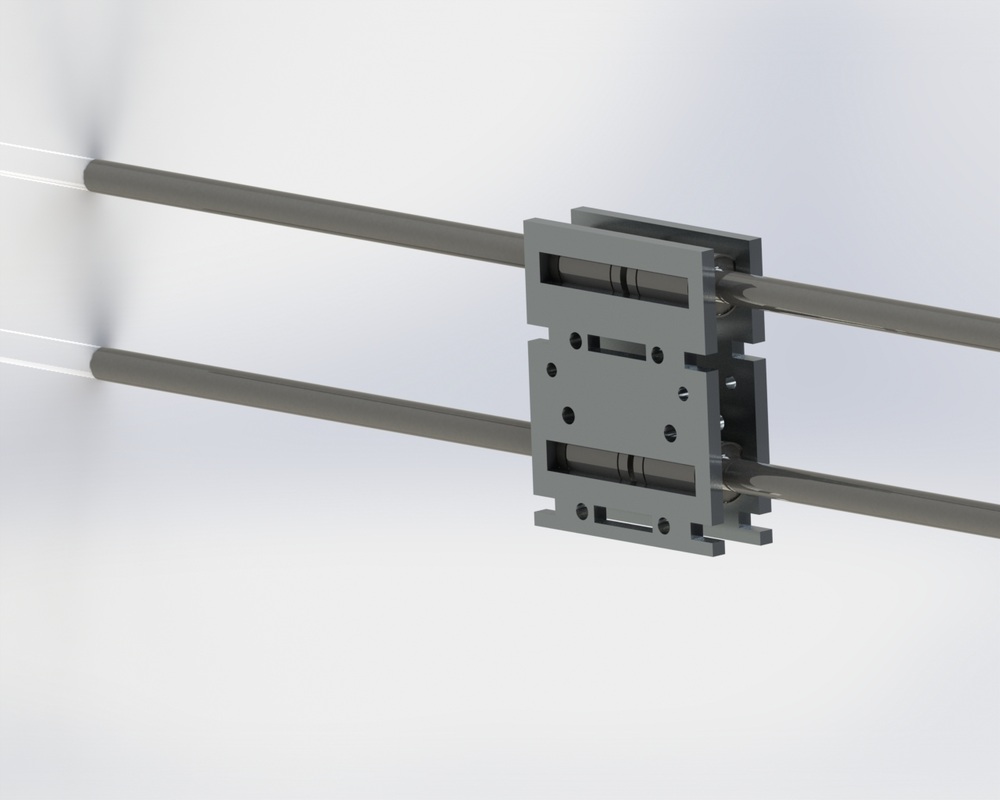

We would like to introduce you to the new release of the Aluminum X carriage.

This improvement will make the x-carriage very flexible and capable of accommodating most of the popular extruders available on the market for the Prusa i3

This improvement will make the x-carriage very flexible and capable of accommodating most of the popular extruders available on the market for the Prusa i3

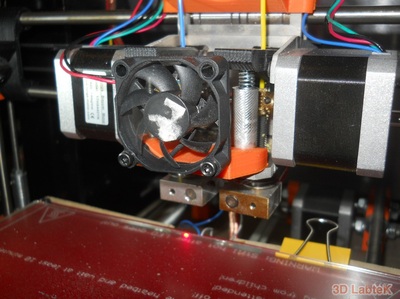

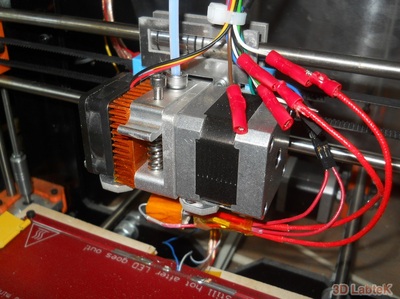

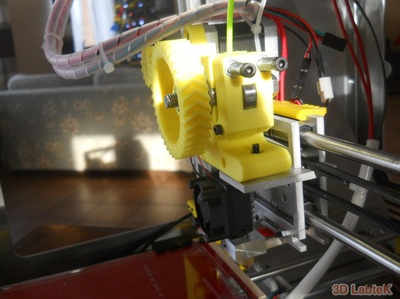

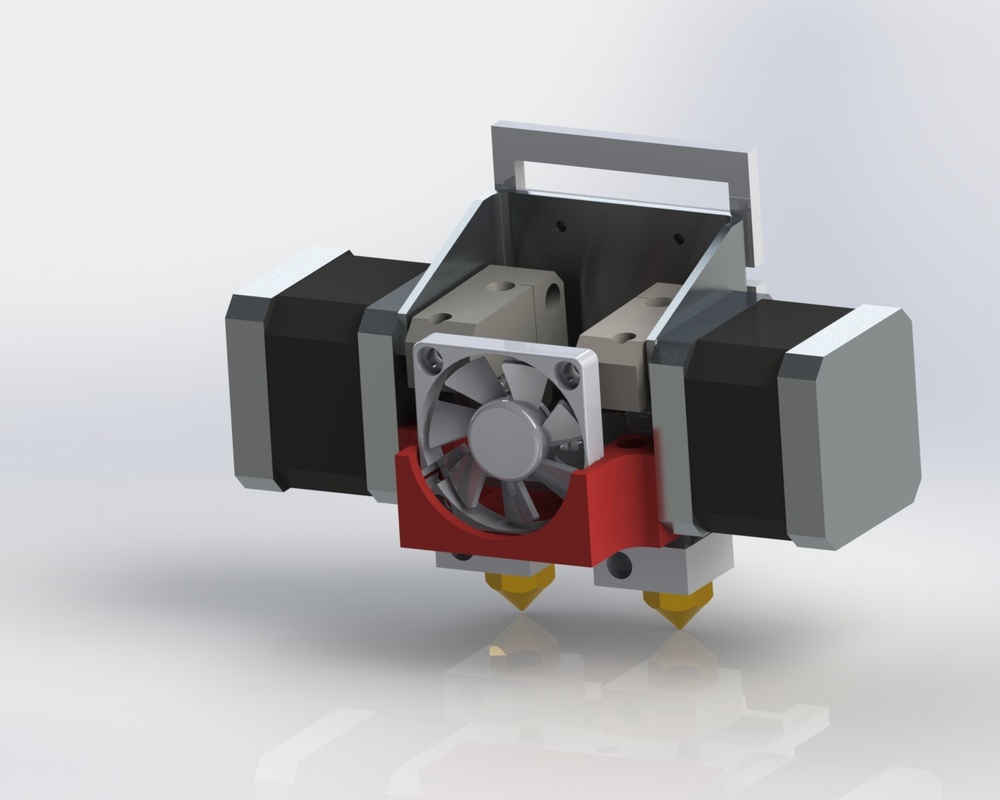

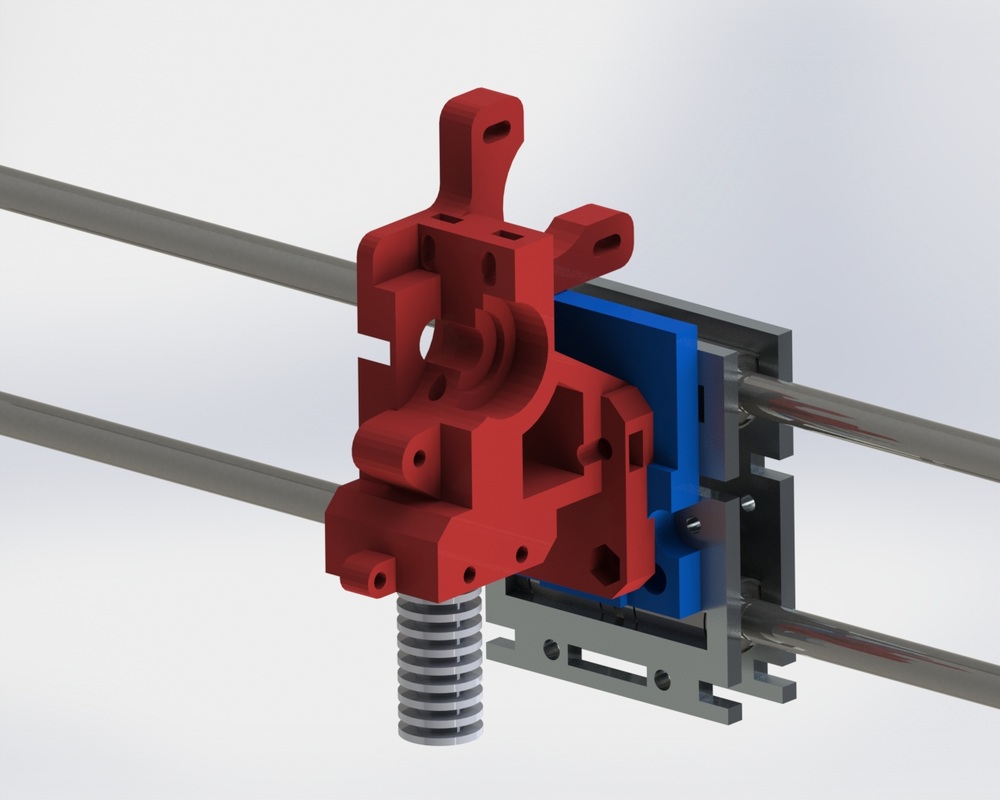

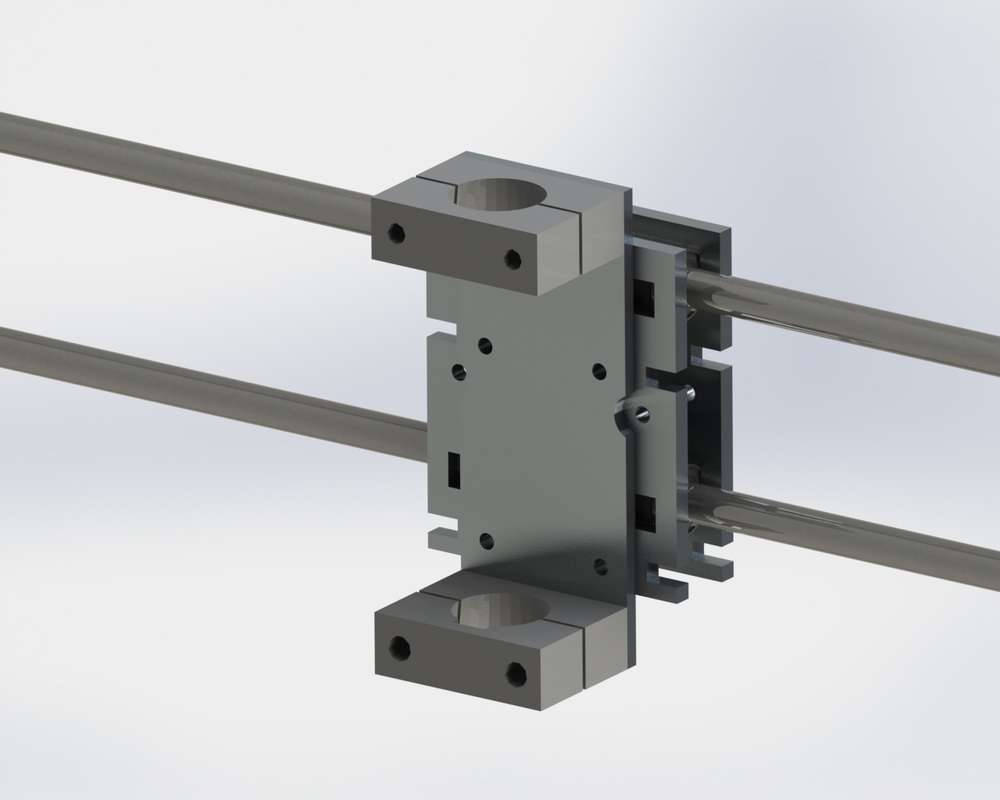

| We have increased the stability adding an additional LM8UU bearing on top so that now it can be installed also on the rework version of the Prusa i3 without dismantling the X axis. This model consists of 3 aluminum plates. One will allow the installation of a classic extruder like the GREG V3 or a direct drive (only for 1,75mm filament) with hot end like the Full metal or the E3D. Generally, all types of hot end that have a groove with internal diameter of 12 mm. The 2nd, bottom plate instead is a new feature of the aluminum X-carriage and it will be able to accommodate a single MK8 direct drive or a double compact extruder ( an extra plate necessary for the installation will be sold separately in the dual extrusion kit). The 3rd plate is a Dremel flex mounting plate, This one allows you to transform your printer in a PCB milling machine just replacing the mount plate. Dual Extruder Dual Extruder with a completely new short hot end. Its design allows easy dismantle of a tip with the barrel without disconnecting a single cable. The heater block has the usual dimension and efficiency, but it slides on the tip and is not threaded anymore on the stainless steel barrel. It allows releasing a grub screw to take out the heater block without disconnecting the thermistors or the heater cartridge. This feature is very useful while making the elevation alignment of the two tips. Very short thermal heat sink placed on top of the tips reduces the thermal conduction on the base plate so that a single 40 mm cooling fan is enough to cool all the area. Motors are isolated from the bottom plate as they are not irradiated by the heat generated by the 2 hot ends. At the moment the dual extruder is in the testing phase and we assume soon will be put on the market.. |

RSS Feed

RSS Feed