After many attempts, endless tests and improvements, heat sink and other stuff,finally we've got a Bowden type extruder working and not oozing.

It was the aim of a little research we made in our workshop.

The tests shown below present various printed parts that were needed to modify the parameters of the system.

Of course we could not expect a perfect result at first print, but it was really not bad.

It was the aim of a little research we made in our workshop.

The tests shown below present various printed parts that were needed to modify the parameters of the system.

Of course we could not expect a perfect result at first print, but it was really not bad.

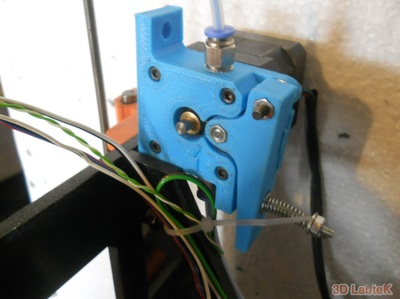

The direct extruder has been completely redesigned from scratch as all the models we looked at on thingiverse were designed for specific printer or specific mount.This model has an indicator of the filament direction and does not need to be opened to insert the filament. All you do is to feed the filament while extruder gear is turning and it will load the filament.

It is available on the left motor mount and the right motor mount so that two extruders can be mounted on both sides of the frame reinforcement.

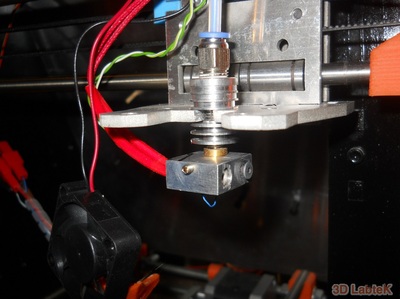

The cooling fan, visible in the first video was removed and replaced with a stronger cooling fan (visible on the round 2) the fan mount just clamps on the upper heat sink with no bolt or nuts

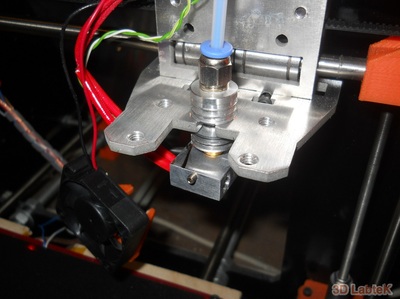

The whole hot end is extremely short, 37 mm from the nozzle up to the top of the aluminum heat sink.

The plate is not the final one as we used the same of the dual direct extruder. In the future we will design a new plate, shorter and lighter capable of accommodating up to 3 bowden hot ends for those who have a card that support 3 hot ends.

It is available on the left motor mount and the right motor mount so that two extruders can be mounted on both sides of the frame reinforcement.

The cooling fan, visible in the first video was removed and replaced with a stronger cooling fan (visible on the round 2) the fan mount just clamps on the upper heat sink with no bolt or nuts

The whole hot end is extremely short, 37 mm from the nozzle up to the top of the aluminum heat sink.

The plate is not the final one as we used the same of the dual direct extruder. In the future we will design a new plate, shorter and lighter capable of accommodating up to 3 bowden hot ends for those who have a card that support 3 hot ends.

| | 1st Round This test marked as round 1 is one of the various tests we performed, but the last design of the tip does not ooze anymore, and it was the aim of the test we were intended to reach. |

| | 2nd Round For the test number two we selected a model with thin walls and a lot of 'z' lifting, the intention was to optimize the parameters, as the first test, it was not oozing but the quality, although better, was not satisfying. So we optimized retraction and extra length on restart, The acceleration also was changed as it is a direct drive with no gear and the behavior is rather different. |

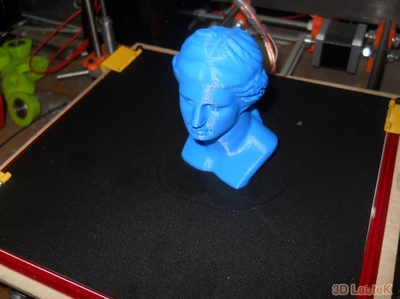

| | 3rd Round Here is the round 3, with the new parameters defined during the previous test. Now it looks pretty good. :-) Part printed at 0,2 mm layer height and 50 mm/sec It took about 2 and half hour but the result is outstanding. |

| Here is the file that we used for this print. |

| ||

RSS Feed

RSS Feed