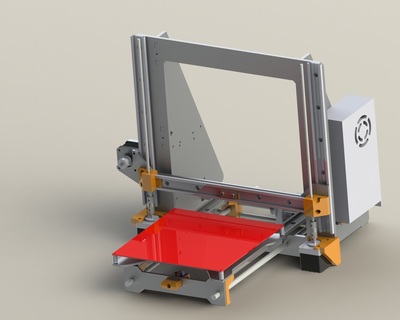

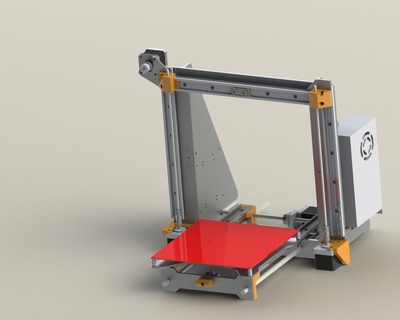

the aim is to get a superior printing quality and an increased printing volume starting from the already good Prusa i3 3D Printer.

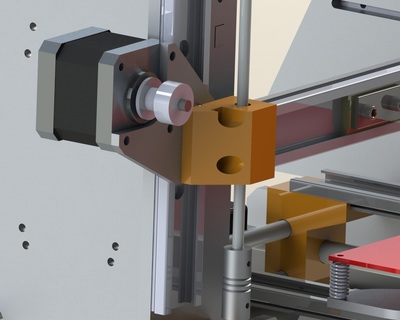

This solution should prevent the wobble artifact and increase the movement precision.

Furthermore there will be no need of lubrication and an incredibly smooth and silent moves while printing

Rather 50 mm more that the actual max Z dimension.

Discussion is open, let us know what you think about!!

RSS Feed

RSS Feed