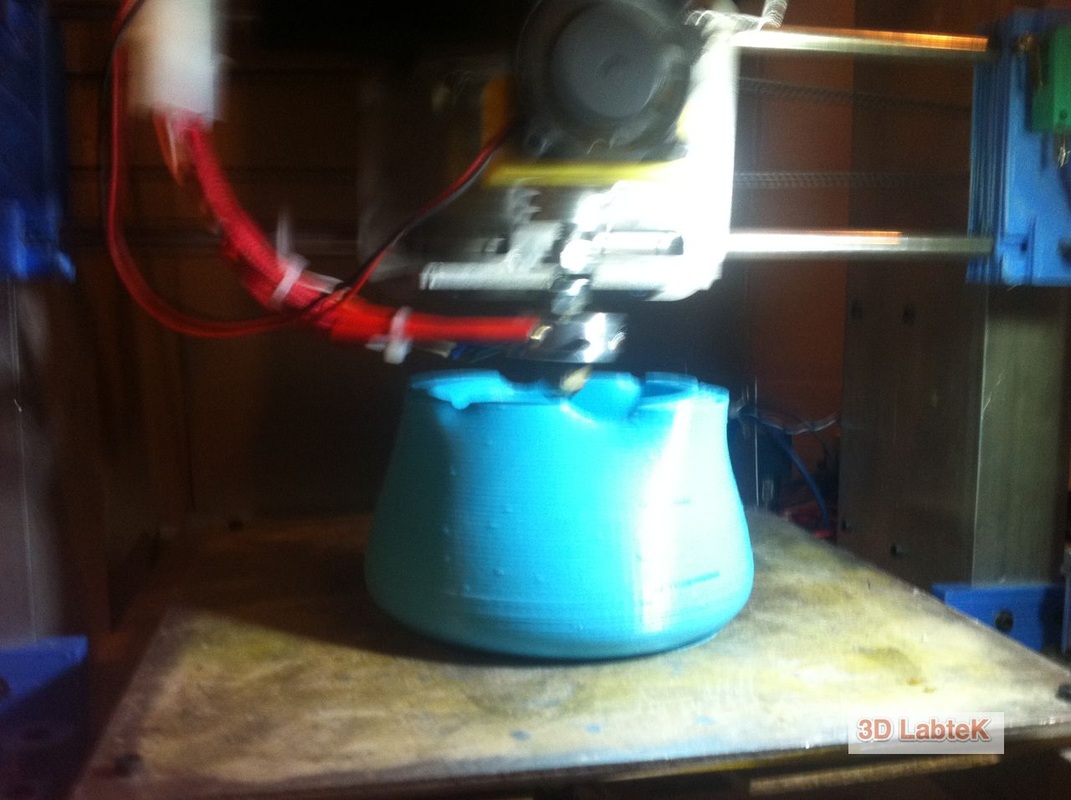

Surface quality test

here is the link http://www.thingiverse.com/thing:26251

| As a starting parameter we settled 0,3 mm layer thickness with a 0,5 mm tip. Printing speed was 50 mm sec for the perimeters and 60 mm for the 0,1 infill, No supports no rafts. During the print we tested different temperature, speed and flow rate, just to verify the effect on the surface. First 100 Layers were printed with a flow rate of 125% and a temperature of 240 degrees, some bubble, especially where the tip finish the external perimeter has came out but very delicate. |

| We reduced the flow rate to 100 % and we increased the seed up to 110%, maintaining the same temperature. There was an improvement- the little bubbles were still present but now almost invisible and the surface get smoother than before. We changed the temperature to 245 degrees and to 250 degrees but without improvement in quality, at 250 degrees we get the same roughness we get with high flow rate. So we get back to 240 degrees. From now on we changed only the the speed increasing up to 140% and decreasing up to 80 % |

| As soon as the other parameters were properly settled the speed change did not affect the surface quality. The hot end we used for this test was equipped with a steel barrel instead of brass and we replaced the two resistors with a very powerful 12 Volts 40 Watt heater, 240 degrees in 2 min 31 second. Judge by yourself. |

RSS Feed

RSS Feed