Sometimes, even with a good printer calibration can happen that during printing it is coming displaced on x-or Y axes, Most of the time this is happening because of mechanical problem. but sometimes the mechanical part is not guilty.

We realize that there is something more than mechanical adjustment to be done after trying to print the same part on different printer and we get the same displacement in the same point.

So we investigate in the firmware playing a bit with acceleration and jerk, but the results was exactly the same.

Thinking that most of our prints are ok, even when we are printing at high speed, we realize that there is something more in some geometry that generate the problem.

Let's get to the point.

In the firmware, for Sanguinololu for example, the maximum frequency is setted to 15000 Hz.

in reality, even if your motors and electronics can bear such a frequency your mechanical parts probably not.

Think the machine is shaking at very high speed for a very short movement, In that moment the maximum frequency is reached and the steps is getting lost.

We realize that this is happening more often on the Y axis, because of the length of the belt,

So we investigate in the firmware playing a bit with acceleration and jerk, but the results was exactly the same.

Thinking that most of our prints are ok, even when we are printing at high speed, we realize that there is something more in some geometry that generate the problem.

Let's get to the point.

In the firmware, for Sanguinololu for example, the maximum frequency is setted to 15000 Hz.

in reality, even if your motors and electronics can bear such a frequency your mechanical parts probably not.

Think the machine is shaking at very high speed for a very short movement, In that moment the maximum frequency is reached and the steps is getting lost.

We realize that this is happening more often on the Y axis, because of the length of the belt,

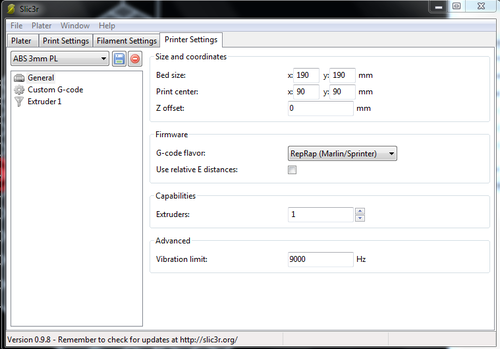

the solution for us was to set the vibration limit in slic3r to 60% of the nominal electronic frequency.

In our case it solved the problem and we printed those parts without any further problem

In our case it solved the problem and we printed those parts without any further problem

RSS Feed

RSS Feed